Gamma-Phase Materials for Advanced Manufacturing

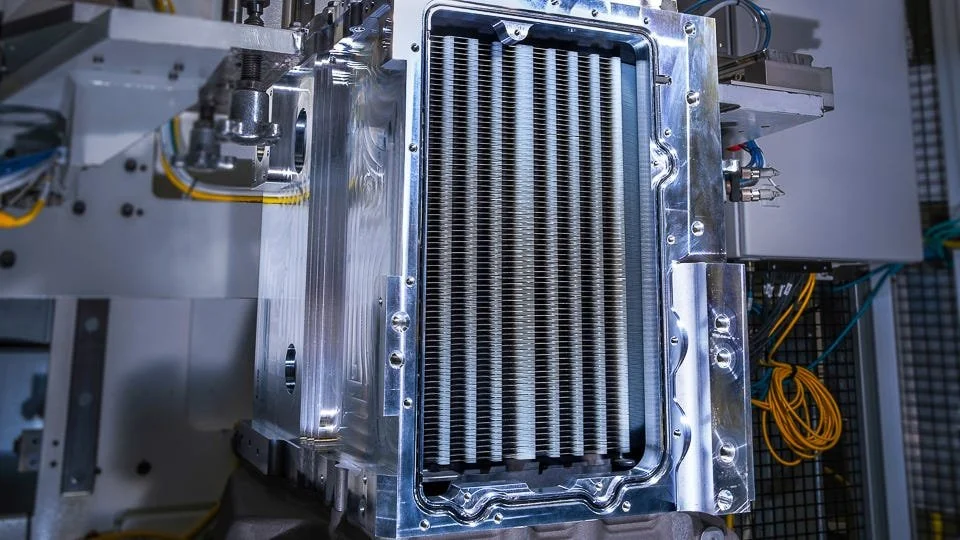

Gamma-phase materials are increasingly critical in advanced engineering, where performance demands require material properties that combine low density with high thermal stability. Conventional materials offer strength but suffer from creep limitations. Gammalite™ materials address these challenges by leveraging transition‑metal stabilization and ceramic reinforcements to achieve a balance of mechanical strength, creep resistance, and oxidation stability.

Purpose Driven Materials

Our mission is to redefine what’s possible in high‑performance materials by advancing a new class of gamma‑phase alloys and ceramics engineered for extreme environments. The GL‑series embodies this commitment, uniting thermally stable gamma‑phase matrices with next‑generation ceramic reinforcement to deliver unprecedented strength‑to‑weight ratios, vibrational damping, and dimensional stability.

This platform exists to give engineers, designers, and manufacturers clear, data‑driven insight into these revolutionary materials. Through transparent performance documentation, rigorous material data sheets, and application‑focused guidance, we empower innovators to evaluate and integrate GL‑series technologies with confidence. Our purpose is simple: accelerate the adoption of advanced gamma‑phase materials that enable lighter, stronger, more resilient systems across defense, aerospace, energy, and next‑generation manufacturing.

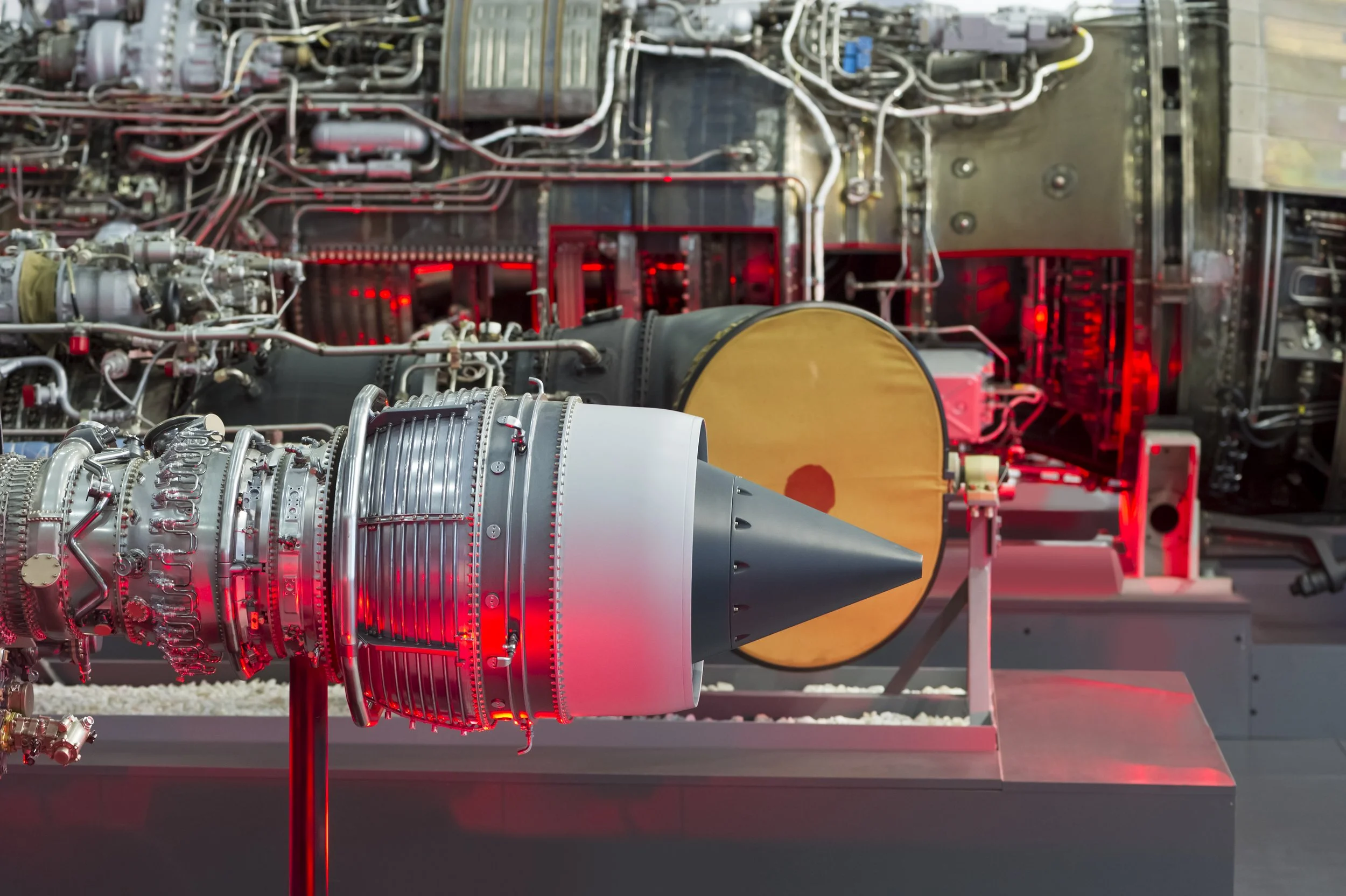

GL 4472 is a titanium rich gamma-phase composite engineered for extreme thermal and mechanical environments. Proprietary nanoceramic dispersoids enhance oxidation resistance, creep stability, and toughness for applications requiring high yield under extreme thermal loading. The composite is stable below 1000 °C with an ultimate tensile strength of 977 MPa and a density of 4.12 g/cm³.

GL 4461 is a titanium rich gamma-phase alloy engineered for extreme thermal and mechanical environments. Transition‑metal stabilizers refine the lamellar titanium structure, providing high strength, creep resistance, and dimensional stability without the use of ceramic dispersoids. The composite is stable below 850 °C with an ultimate tensile strength of 910 MPa and a density of 4.05 g/cm³.

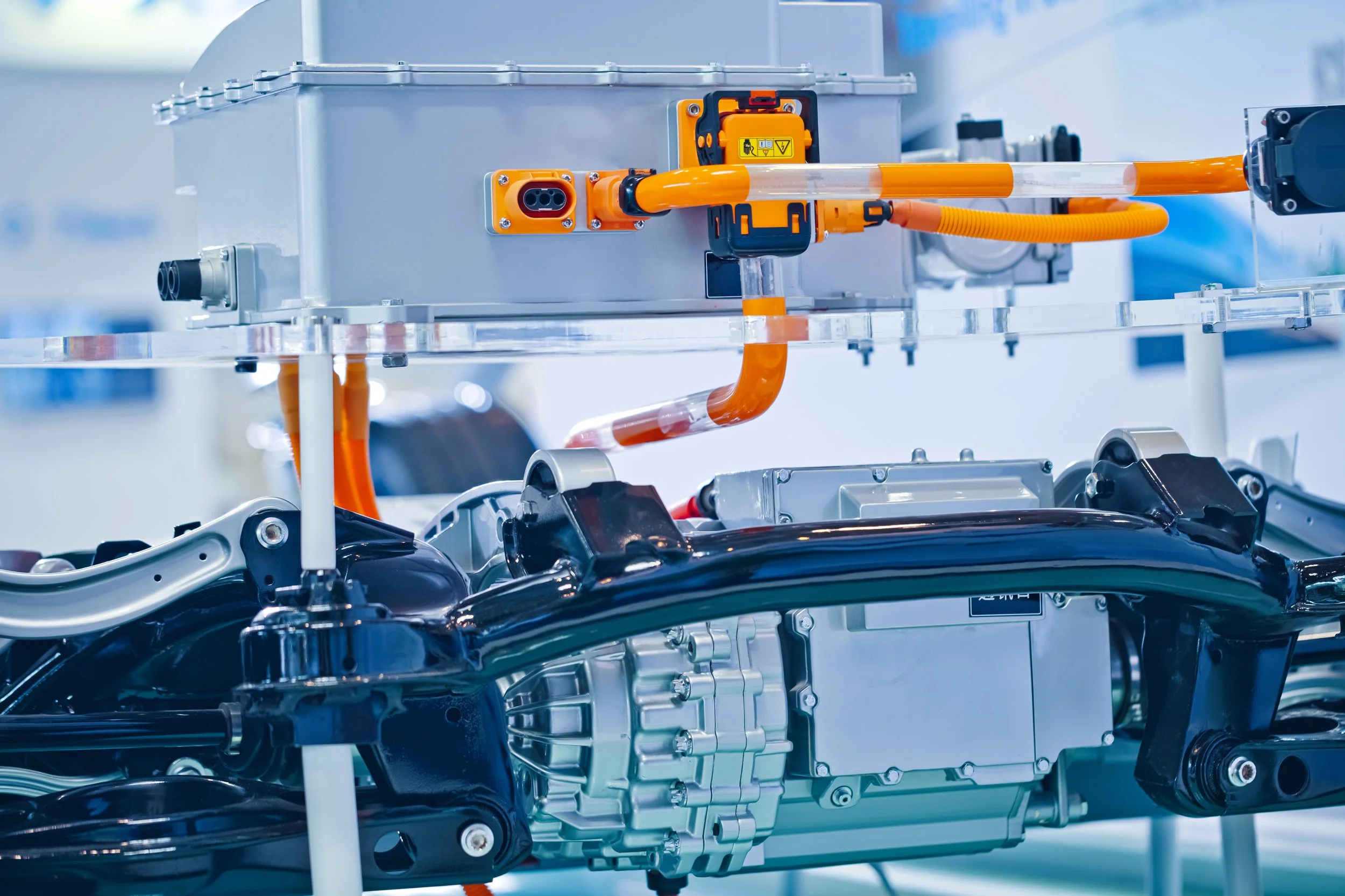

GL 8413 is a magnesium rich gamma-phase lightweight structural composite system designed for applications requiring strength and creep resistance under sustained thermal and mechanical loads. The composite integrates nanoceramic dispersoids to stabilize microstructures and enhance oxidation resistance. The composite is stable below 350 °C with an ultimate tensile strength of 705 MPa and a density of 1.97 g/cm³.

GL 8410 is a magnesium rich gamma-phase lightweight structural alloy system designed for high-performance applications requiring strength, creep resistance, and oxidation stability under sustained thermal and mechanical loads. The alloy integrates rare-earth elements to stabilize microstructures and prevent grain boundary sliding. The alloy is stable below 350 °C with an ultimate tensile strength of 600 MPa and a density of 1.93 g/cm³.

Contact Us

Our conversation starts with the technical information available on this site, including the full material data sheets, performance summaries, and application notes. These resources provide engineers and manufacturers with the foundational understanding needed to evaluate whether our gamma‑phase materials align with their performance goals. Once you’ve reviewed the available data, the next step is to schedule a discussion with our engineering team. We’ll work with you to understand your specific application, explore design considerations, and determine the best path forward for integrating our technology into your system.