GAMMALITE™GL 4461

Titanium continues to grow in strategic importance across advanced engineering sectors, where next‑generation systems demand materials that unite low density, thermal stability, and long‑duration mechanical integrity. Although conventional titanium alloys provide strong room‑temperature performance, they remain limited by creep deformation, oxide instability, and microstructural coarsening at elevated temperatures. GL 4461 represents a major advancement in titanium‑based alloy technology, combining transition‑metal stabilization to refine the lamellar titanium structure. Its engineered microstructure—featuring refined lamellar colonies and stabilized intermetallic phases—produces superior creep resistance, oxidation stability, lamellar refinement, and improved dimensional stability under cyclic thermal loading. With a density of 4.05 g/cm³, an ultimate tensile strength of 910 MPa, yield strength of 505 MPa, hardness of 390 HV, elastic modulus of 178 GPa, and demonstrated creep stability to 850 °C, GL 4461 is positioned as a versatile and robust solution for aerospace turbine housings, automotive turbocharger shells, energy exchanger plates, and defense barrel liners, each supported by tailored forming process flows.

Alloy Structure

GL 4461 is a proprietary Gammalite™ alloy stabilized exclusively through transition‑metal chemistry. Its foundation is a gamma‑titanium (γ‑TiAl) crystal structure, an ordered intermetallic phase known for its exceptional strength‑to‑weight ratio and inherent resistance to thermal degradation. This γ‑phase framework provides the alloy with a stable, tightly bonded lattice that maintains mechanical integrity even under sustained high temperatures and cyclic loading.

Unlike dispersion‑strengthened materials that rely on ceramic particles for stability, GL 4461 achieves its performance entirely through controlled alloying and phase engineering. Transition‑metal additions tune the balance between γ‑TiAl and its companion phases, refining lamellar structures, suppressing unwanted brittleness, and enhancing creep resistance without introducing secondary ceramic reinforcements. This approach results in a cleaner, more uniform microstructure with predictable behavior during casting, heat treatment, and long‑term service.

GL 4461 can be cast to general shapes with good quality when thermal gradients and cooling rates are controlled. Post-cast homogenization is recommended to alleviate segregation, stabilize the gamma-phase intermetallic framework, and prepare the microstructure for subsequent deformation or heat treatment. Casting is a viable starting route for components that will be refined by forging.

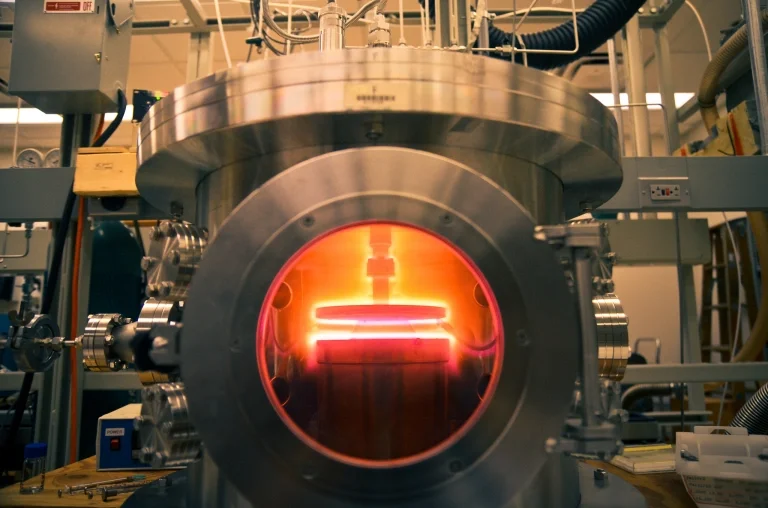

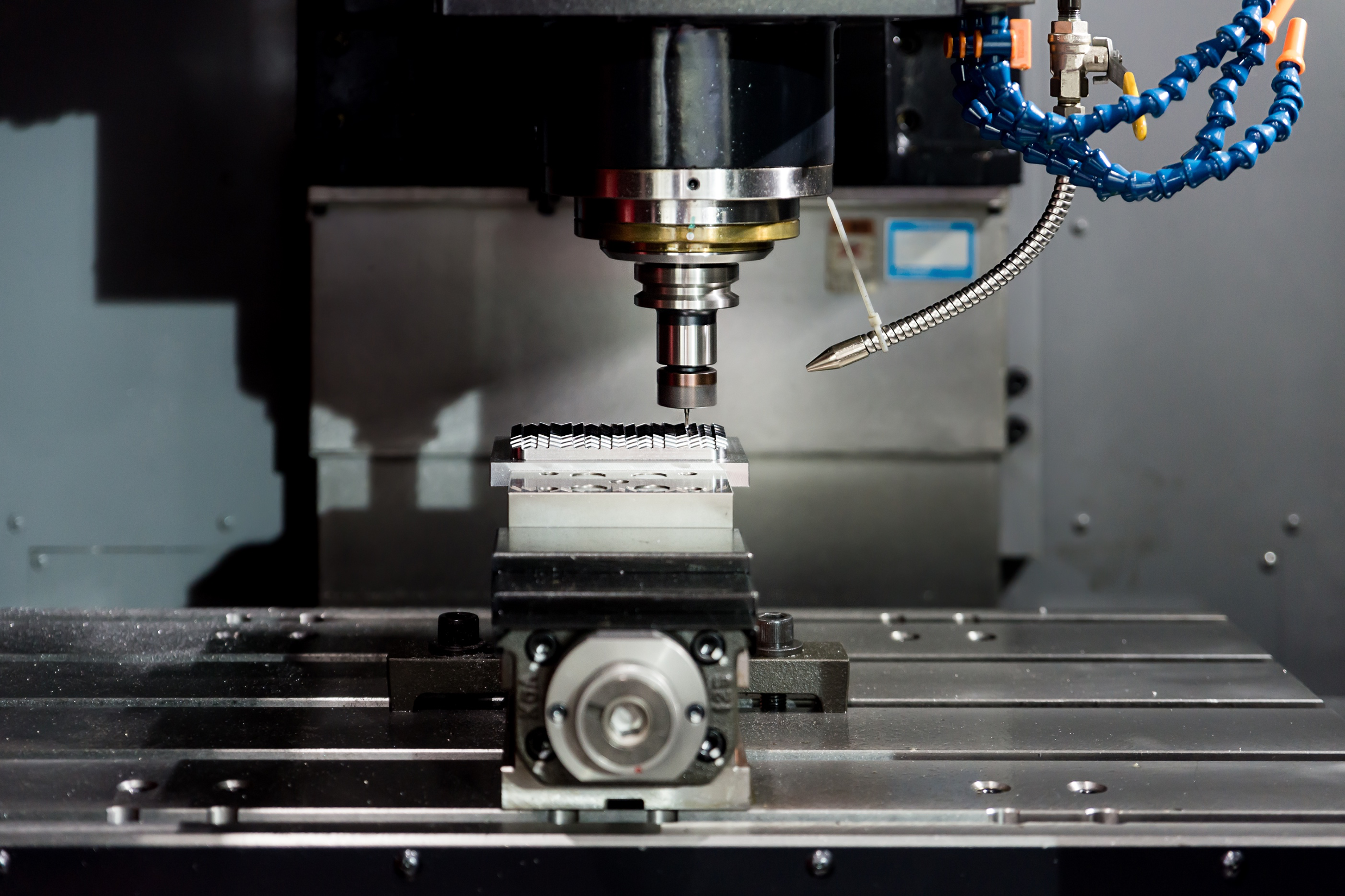

FAST enables rapid densification of GL 4461 powder under simultaneous electrical current and pressure, producing dense billets with refined grains and stable intermetallic phases. For the alloy variant, FAST is particularly effective as a billet‑consolidation step prior to extrusion or forging, where the simplified chemistry (no ceramic dispersoids) streamlines parameter control. FAST can also form complex near‑net shapes that are finished via CNC machining to tight tolerances.

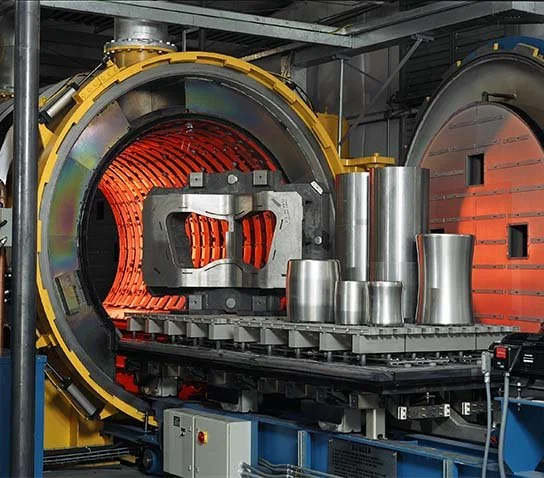

Forging of GL 4461 (from cast or FAST‑consolidated billets) improves toughness, fatigue performance, and dimensional stability. Moderate strain rates with appropriate thermal conditioning help maintain the gamma‑phase stability and limit grain coarsening. Closed‑die or open‑die forging can achieve near‑net geometries for brackets, housings, and load‑bearing components where creep resistance to ~325–350 °C is required.

Extrusion is limited for GL 4461, generally promoting microstructural refinement and mechanical uniformity along the flow direction. Elevated temperature with controlled strain rate yields continuous general profiles, tubes, and casings with consistent wall thickness and improved fatigue resistance. Low to medium ratio extrusion can develop weak-to-moderate texture that enhances strength without compromising toughness.

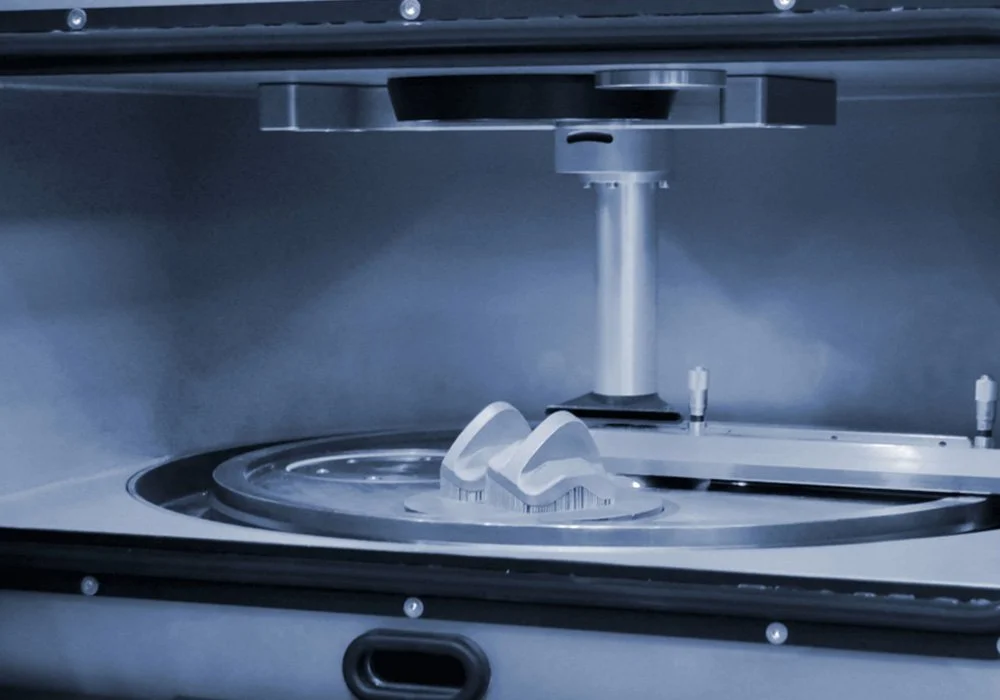

Powder‑bed fusion (e.g., SLM) and binder jet routes are applicable to GL 4461 for lattices, conformal channels, and complex internal features not achievable by machining. Parameter optimization focuses on densification, microcrack suppression, and oxidation control, followed by heat treatment to stabilize phases and enhance mechanical performance. Printed parts are typically finish‑machined to final tolerance and surface quality.

GL 4461 responds well to solution treatment, quenching, and aging to reach peak strength. Solutionizing dissolves solute‑rich phases and homogenizes the matrix, while quenching retains a supersaturated solid solution for subsequent precipitation during aging. Tailored aging schedules balance yield strength, UTS, and ductility, supporting creep resistance up to ~325–350 °C.

GL 4461 machines cleanly with high wear tooling (PCD, etc.). The alloy’s stable intermetallic framework supports tight tolerances and consistent surface finish across turning, milling, drilling, and threading. Standard coolant and chip-control practices are sufficient, while post-machining stress-relief or peening may be applied to mitigate residual stress for environments prone to stress corrosion.

Weldability is limited and requires compatible filler metals and appropriate shielding gas to preserve oxidation resistance and avoid hot cracking. Pre‑weld cleaning and controlled heat input reduce defect formation and microstructural softening adjacent to the fusion zone. Where practical, designers should prefer mechanical joining or weld‑free architectures; if welding is essential, procedure qualification is strongly recommended.

GL 4461 is compatible with anodizing, electrophoretic coatings, conversion coatings, and metal plating to enhance corrosion resistance and wear durability. Anodizing improves surface hardness and corrosion resistance; e‑coats offer uniform coverage on complex geometries; conversion coatings promote paint/adhesive bond strength; and nickel/chrome plating provides additional wear protection. In marine or galvanically aggressive environments, coatings and isolation strategies are recommended to manage corrosion risk.

Aerospace Turbine Housings

GL 4461 is particularly well‑suited for aerospace turbine housings, which must withstand prolonged exposure to extreme thermal environments, mechanical vibration, and cyclic loading. The alloy’s transition‑metal stabilization maintains phase integrity and prevents microstructural drift during repeated thermal cycling, ensuring dimensional stability and reliable fit within high‑precision assemblies. Its creep resistance up to 850 °C under sustained stress allows turbine housings to retain mechanical strength and resist deformation even during extended high‑power operation. The relatively low density of 4.05 g/cm³ reduces overall component mass, directly contributing to improved thrust‑to‑weight ratios, fuel efficiency, and payload capacity. In addition, the alloy’s thermal conductivity supports effective heat dissipation, mitigating localized hot spots and extending service life. Combined with its compatibility with advanced processing routes such as FAST, extrusion, and forging, GL 4461 enables near‑net‑shape housings with refined grain structures, high fatigue resistance, and reduced machining requirements. This integrated performance profile makes GL 4461 a strategic material choice for next‑generation aerospace propulsion systems where efficiency, durability, and weight savings are critical.

Automotive Turbocharger Shells

In automotive engineering, GL 4461 offers a robust solution for turbocharger shells that operate under extreme exhaust gas temperatures and rapid thermal cycling. The alloy’s transition‑metal stabilization ensures phase stability and prevents microstructural degradation, allowing shells to maintain dimensional accuracy even during prolonged exposure to high‑velocity exhaust streams. Its creep resistance up to 850 °C under sustained stress prevents distortion and cracking, while oxidation stability protects against scale formation and surface degradation, extending service life in aggressive combustion environments. The relatively low density of 4.05 g/cm³ reduces component mass, which directly enhances engine responsiveness, acceleration, and overall vehicle efficiency. Additionally, GL 4461’s thermal conductivity supports effective heat dissipation, mitigating localized hot spots that can compromise performance. The alloy’s compatibility with extrusion and forging routes enables the production of thin‑walled, lightweight casings with uniform mechanical properties, while CNC machining ensures precise tolerances for integration into high‑performance turbo systems. Together, these attributes make GL 4461 an advanced material choice for next‑generation turbocharger shells, balancing durability, efficiency, and manufacturability in demanding automotive applications.

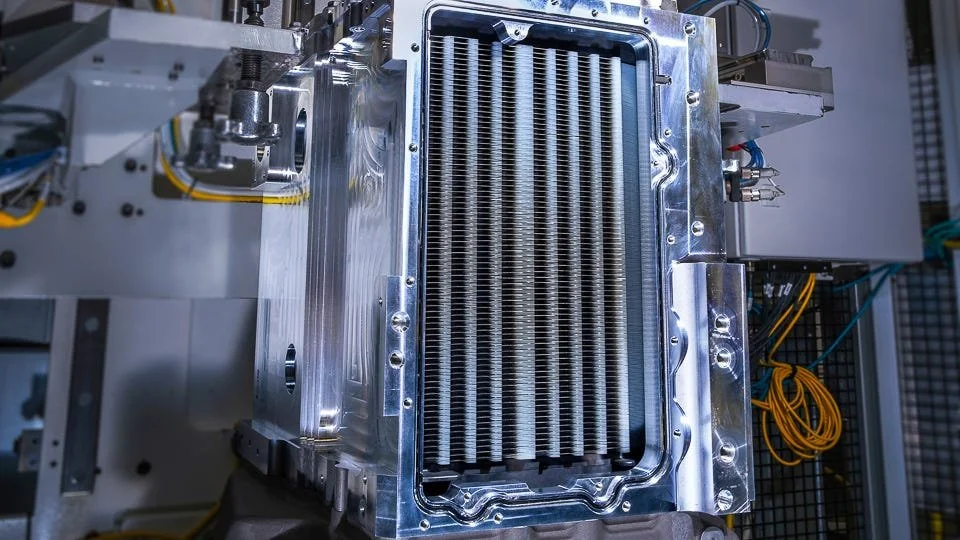

Energy Exchanger Plates

GL 4461 is highly effective for energy exchanger plates deployed in concentrated solar power (CSP) systems and advanced heat recovery platforms, where components must endure cyclic thermal shocks and sustained exposure to elevated temperatures. The alloy’s thermal conductivity of 15.1 W/m·K enables efficient transfer of heat across exchanger surfaces, improving system output and reducing energy losses. Its specific heat capacity of 0.57 J/g·K provides thermal buffering, allowing the plates to absorb and release heat smoothly during rapid temperature fluctuations, thereby protecting against thermal fatigue and dimensional instability. Transition‑metal stabilization ensures microstructural integrity under repeated heating and cooling cycles, preventing phase drift and grain coarsening that could compromise long‑term performance. The relatively low density of 4.05 g/cm³ reduces structural mass, which is advantageous for large‑scale installations where weight savings translate into easier handling, reduced support requirements, and lower overall system costs. GL 4461’s compatibility with FAST and machining routes allows the creation of exchanger plates with intricate channels and manifolds, enabling precise control of heat flow and fluid dynamics. Together, these attributes make GL 4461 a strategic material for next‑generation energy platforms, delivering durability, efficiency, and reliability in demanding thermal management environments.

Small Arms Barrel Manufacturing

For defense applications, GL 4461 presents a strong candidate for barrels and suppressors that must endure rapid‑fire conditions, cyclic thermal loads, and intense mechanical stresses. The alloy’s transition‑metal stabilization preserves microstructural integrity under repeated heating and cooling, preventing phase instability and dimensional distortion that can compromise accuracy. Its creep resistance up to 850 °C ensures that liners retain mechanical strength during sustained firing sequences, while oxidation stability minimizes surface degradation and scaling in high‑temperature combustion environments. The relatively low density of 4.05 g/cm³ reduces overall weapon system mass, lowering soldier burden and improving maneuverability in field operations. Enhanced thermal conductivity supports efficient heat dissipation, reducing localized hot spots that accelerate wear and extending service life between maintenance cycles. GL 4461’s compatibility with forging and additive manufacturing routes allows the production of components with tailored geometries, optimized flow paths, and precision tolerances, ensuring consistent ballistic performance. Together, these attributes make GL 4461 a strategic material for next‑generation small arms barrels and suppressors, balancing durability, lightweight construction, and operational reliability in demanding combat environments.