GAMMALITE™GL 8413

GL 8413 Gammalite™ Composite represents the evolution of lightweight structural systems, engineered for environments where both strength and dimensional stability must be preserved under extreme thermal and mechanical loads. Unlike GL 8410, which relies solely on rare‑earth enrichment and gamma‑phase stabilization, GL 8413 integrates a ceramic‑reinforced gamma‑phase matrix to achieve a balance of stiffness, toughness, and long‑term reliability. At its core, GL 8413 is built on a stabilized gamma‑phase intermetallic framework, providing the ordered lattice structure necessary to resist creep, deformation, and microstructural coarsening. This backbone is further enhanced by finely dispersed ceramic reinforcements, which act as load‑bearing stiffeners, grain‑boundary stabilizers, and erosion‑resistant phases. The result is a composite microstructure that combines the high‑temperature stability of rare‑earth intermetallics with the modulus and wear resistance of advanced ceramics. This dual‑reinforcement strategy yields a material with exceptional tensile and yield strength, improved creep resistance, and enhanced oxidation performance, while maintaining a low density. With a density of 1.97 g/cm³, an ultimate tensile strength of 705 MPa, yield strength of 640 MPa, hardness of 205 HV, elastic modulus of 75 GPa, and demonstrated creep stability to 350 °C, GL 8413 is an ideal candidate for engine mounts and structural frames, lightweight armor plates, exhaust manifolds, and electronics housings.

Composite Structure and Dispersoids

GL 8413 is a proprietary lightweight metal composite enriched with rare‑earth elements and strengthened by uniformly dispersed ceramic particles. The material is built around a stabilized gamma‑phase intermetallic framework, a highly ordered structure that delivers exceptional high‑temperature strength, creep resistance, and dimensional stability under prolonged thermal and mechanical loads. Within this gamma matrix, the nanoceramic dispersoids play three critical roles: they pin grain boundaries to prevent coarsening during thermal cycling, they enhance oxidation resistance by forming stable surface oxides that reduce ignition risk, and they contribute to thermal buffering by increasing the composite’s effective heat capacity and moderating temperature spikes during rapid heating. The rare‑earth‑stabilized gamma phase provides a rigid, thermally resilient backbone, while the ceramic dispersoids introduce complementary improvements in microstructural stability and thermal management. Together, this hybrid architecture yields a composite that is simultaneously strong, oxidation‑resistant, and thermally robust, making GL 8413 well‑suited for demanding aerospace, defense, automotive, and energy applications where lightweight materials must endure extreme environments.

GL 8413 can be cast to general shapes with good quality when thermal gradients and cooling rates are controlled. Post-cast homogenization is recommended to alleviate segregation, stabilize the gamma-phase intermetallic framework, and prepare the microstructure for subsequent deformation or heat treatment. Casting is a viable starting route for components that will be refined by extrusion or forging.

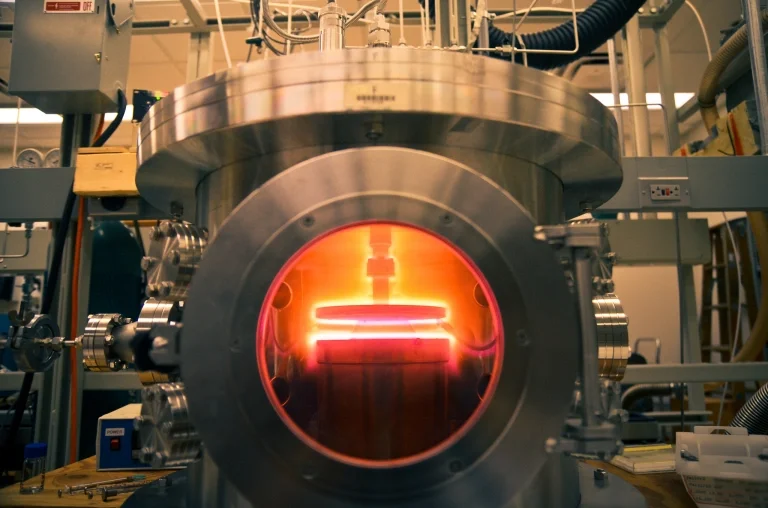

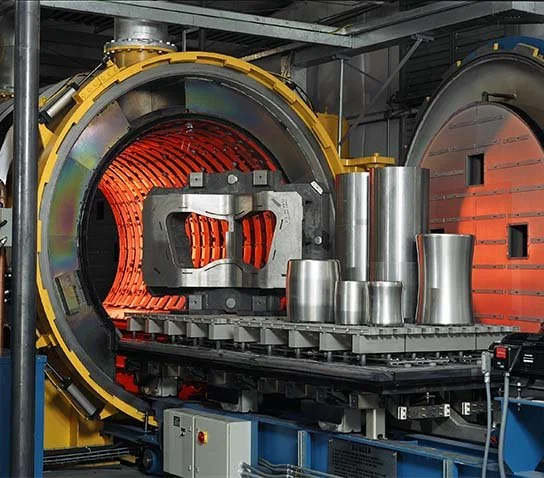

FAST provides rapid densification under simultaneous pressure and electrical current. For GL 8413, FAST produces dense billets with refined grain structures and stable intermetallic phases. Beyond simple billets, FAST can also form complex 3D near‑net‑shapes, reducing the need for extensive secondary machining. This capability allows intricate geometries to be produced directly from powder, enabling components such as aerospace brackets, energy system housings, and custom thermal management blocks.

Forging GL 8413 elevates the material into a truly structural composite by tightening and densifying the gamma‑phase matrix while preserving the uniform distribution of ceramic dispersoids. The process enhances toughness, improves fatigue resistance, and delivers superior dimensional stability under cyclic thermal and mechanical loads. These gains make forged GL 8413 an excellent choice for aerospace brackets, automotive housings, precision mounts, and other load‑bearing components.

Extruding GL 8413 produces a refined, directionally strengthened form of the material that takes full advantage of its gamma‑phase matrix and ceramic dispersoid architecture. The intense shear and consolidation during extrusion break up residual porosity, align the microstructure, and distribute the dispersoids even more uniformly along the flow direction. This results in higher toughness, improved fatigue life, and excellent dimensional consistency across long sections. The process also enhances load‑transfer efficiency between the gamma‑phase backbone and the ceramic dispersoids.l.

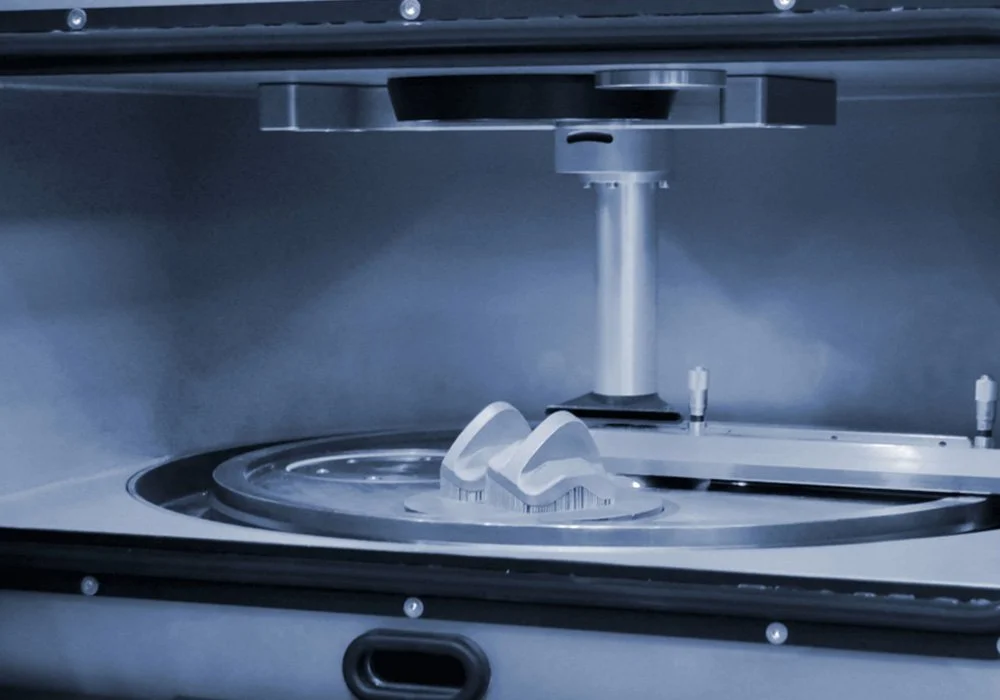

Additive manufacturing of GL 8413 enables complex geometries and lightweight architectures that cannot be produced through conventional forming routes. During layer‑by‑layer consolidation, the gamma‑phase matrix and ceramic dispersoids solidify into a finely structured microarchitecture with excellent dimensional precision. The rapid thermal cycling inherent to 3D printing promotes ultrafine grain formation, while the dispersoids remain uniformly suspended within the gamma matrix, continuing to pin grain boundaries and stabilize the microstructure.

Heat treatment of GL 8413 enhances the stability and performance of its gamma‑phase matrix while optimizing the interaction between rare‑earth intermetallics and ceramic dispersoids. Controlled thermal cycles refine the gamma‑phase distribution, relieve internal stresses, and promote a more uniform, coherent microstructure. During these treatments, the ceramic dispersoids continue to pin grain boundaries and suppress coarsening, allowing the alloy to retain its ultrafine structure even after repeated exposure to elevated temperatures.

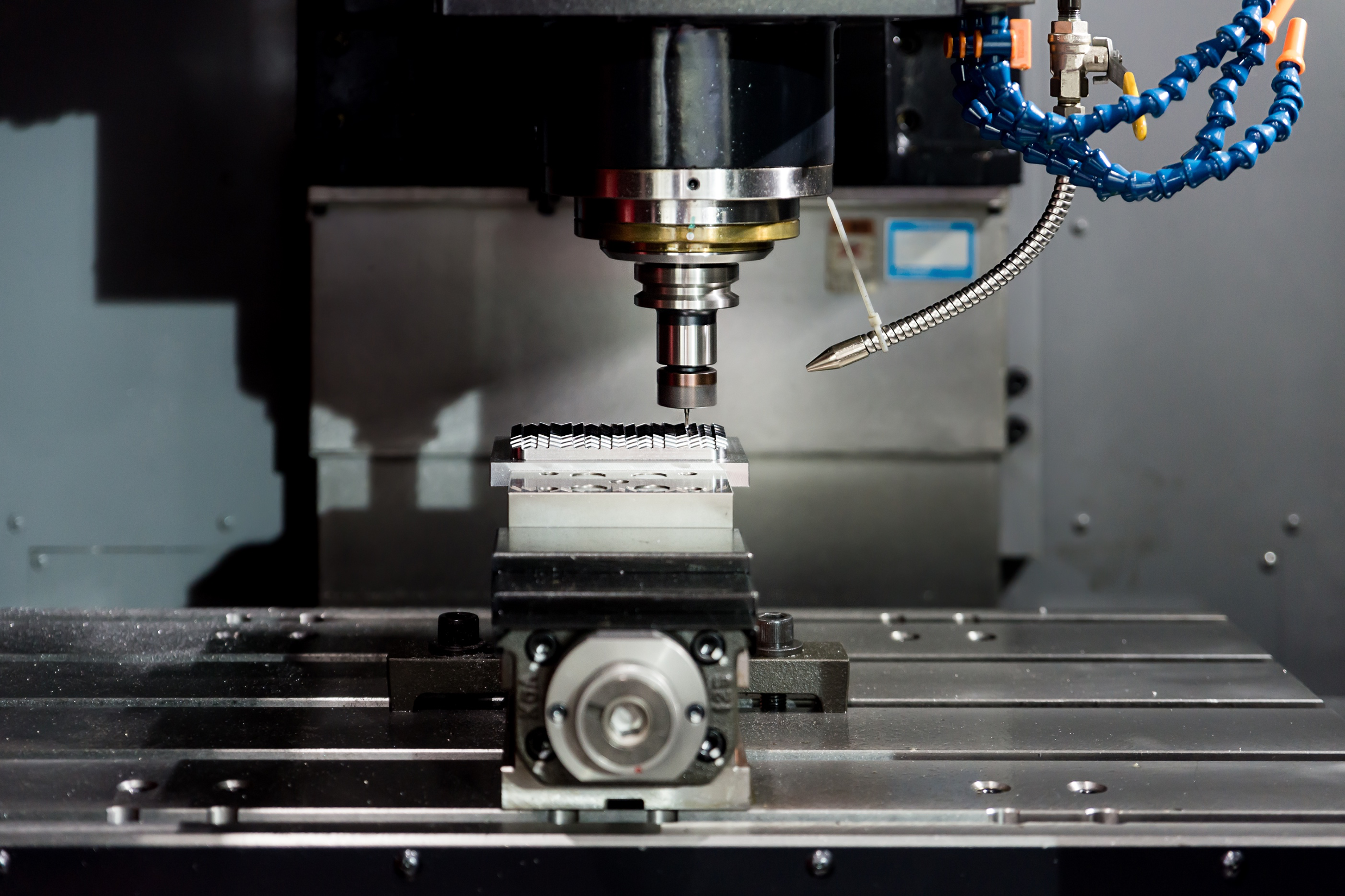

GL 8413 machines cleanly with conventional tooling; no special tooling is required. The alloy’s stable intermetallic framework supported with ceramic dispersoids affords tight tolerances and consistent surface finish across turning, milling, drilling, and threading. Standard coolant and chip-control practices are sufficient. Typically, feeds and speeds are increased by ~80% compared to traditional aluminum alloy machining.

Weldability is limited and requires compatible filler metals and appropriate shielding gas to preserve oxidation resistance and avoid hot cracking. Pre-weld cleaning and controlled heat input reduce defect formation and microstructural softening adjacent to the fusion zone. Where practical, designers should prefer mechanical joining or weld-free architectures; if welding is essential, procedure qualification is strongly recommended.

GL 8413 is compatible with anodizing, electrophoretic coatings, conversion coatings, and metal plating to enhance corrosion resistance and wear durability. Anodizing improves surface hardness and corrosion resistance; e-coats offer uniform coverage on complex geometries; conversion coatings promote paint/adhesive bond strength; and nickel/chrome plating provides additional wear protection. In marine or galvanically aggressive environments, coatings and isolation strategies are recommended to manage corrosion risk.

Aerospace Thermal Shield FAST Forged

In aerospace engineering, structural brackets and thermal shielding panels are critical components that must balance lightweight design with exceptional mechanical and thermal stability. Every pound saved translates directly into increased payload capacity, extended range, or reduced fuel consumption, making weight reduction a primary driver in material selection. At the same time, these parts are exposed to sustained high temperatures, cyclic thermal shocks, and mechanical stresses during flight and orbital service, requiring materials that resist creep, fatigue, and oxidation. GL 8413 billets consolidated by Field Assisted Sintering Technology (FAST) provide a dense, refined microstructure that serves as an ideal precursor for further shaping. Once consolidated, these billets can be forged or extruded into near‑net‑shape brackets and panels, minimizing machining requirements and ensuring dimensional stability. The forging process after FAST densification enhances toughness, fatigue resistance, and impact tolerance, ensuring that the components can withstand vibration, launch stresses, and long‑term service loads.

The material’s rare‑earth intermetallic phases play a central role in resisting creep deformation during extended missions. These phases stabilize grain boundaries and suppress sliding mechanisms that typically degrade lightweight alloys at elevated temperatures. Complementing this, the uniformly distributed ceramic dispersoids act as microstructural anchors, pinning grains and preventing coarsening under orbital thermal cycling. This dual reinforcement system ensures that the brackets and shields maintain their mechanical integrity even after thousands of thermal cycles in space. For thermal shielding applications, GL 8413’s enhanced specific heat capacity and thermal conductivity provide additional benefits. The material buffers rapid temperature fluctuations, reducing thermal gradients across panels and lowering the risk of distortion or cracking. This makes it particularly well‑suited for spacecraft exteriors, satellite housings, and aircraft engine compartments where thermal management is critical.

Suppressors Formed Through Additive Solutions

Modern suppressors are subjected to moderate cyclic thermal loads, where temperatures can spike hundreds of degrees in seconds and repeat over thousands of firing cycles. Traditional materials such as titanium, while strong, often struggle to manage these rapid thermal fluctuations without distortion, oxidation, or performance degradation. GL 8413 addresses these challenges by combining high specific heat capacity, elevated thermal conductivity, and increased mechanical strength enabling suppressors to absorb, store, and dissipate heat more effectively than conventional alloys. This dual property reduces localized hot spots, delays thermal saturation, and improves shooter safety and suppressor longevity. Further, the low material density allows for thicker structures while enabling weight savings to manage thermal loads. The adoption of additive manufacturing (AM) unlocks design freedoms that conventional machining cannot achieve. With GL 8413 powders, engineers can print suppressors featuring intricate internal flow paths, lattice structures, and optimized baffle geometries. The composite’s rare‑earth intermetallic phases provide creep resistance under sustained thermal stress, ensuring dimensional stability even during prolonged rapid‑fire sequences. Meanwhile, the uniformly distributed ceramic dispersoids pin grain boundaries and prevent coarsening, maintaining microstructural integrity under repeated heating and cooling cycles. Together, these reinforcements deliver a suppressor that resists thermal fatigue, oxidation, and erosion from combustion gases far better than titanium or steel alternatives. Operationally, GL 8413’s lightweight nature significantly reduces soldier burden in field conditions. A suppressor fabricated from this composite can weigh substantially less than a steel equivalent, improving weapon balance and reducing fatigue during extended missions. The combination of durability, thermal resilience, and weight savings makes GL 8413 suppressors particularly valuable for defense applications, where reliability under extreme conditions is non‑negotiable and every ounce of weight matters.

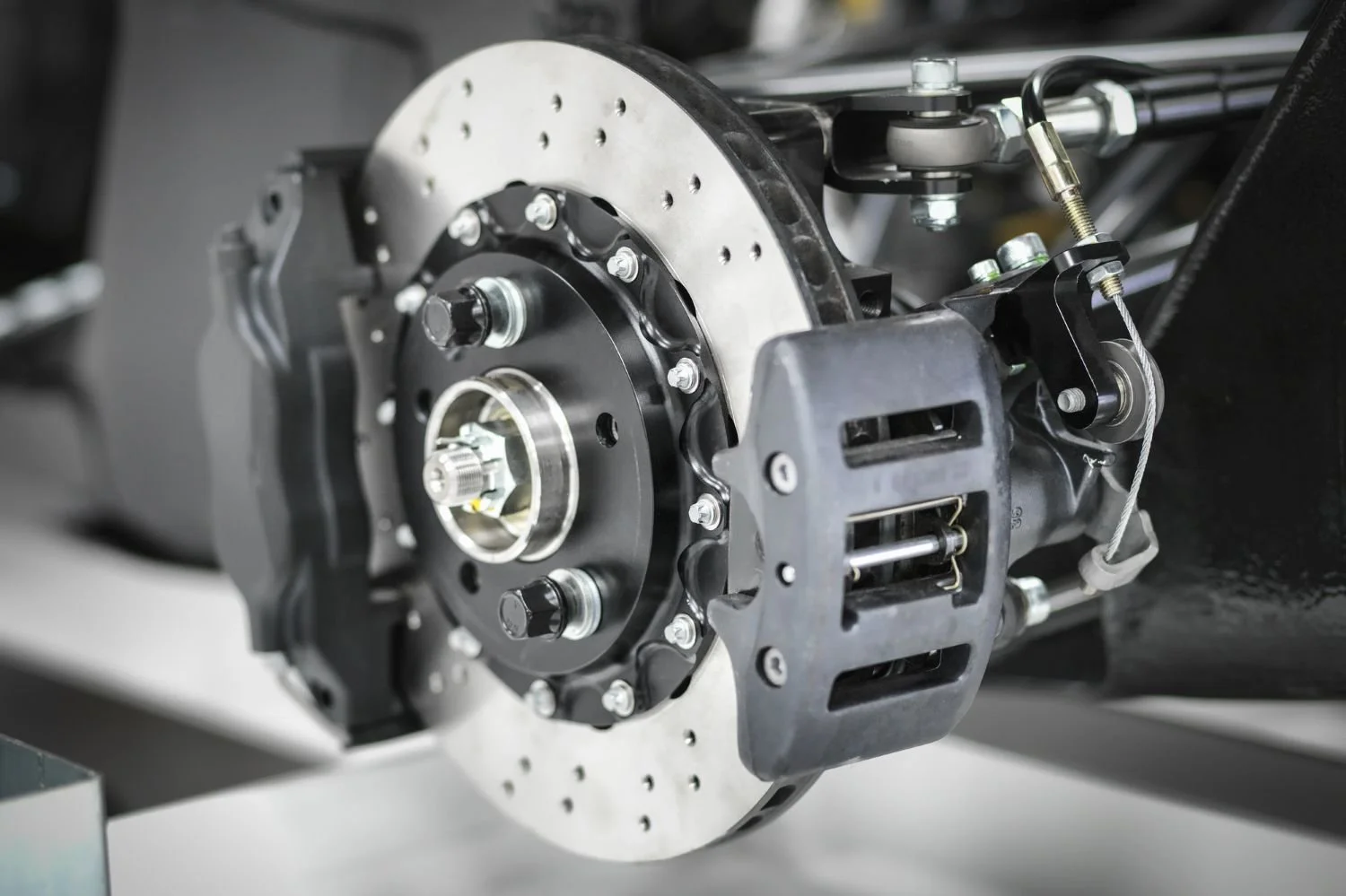

Brake Calipers FAST Forged

Modern performance vehicles demand braking systems that combine lightweight construction with high mechanical stability. Brake calipers, in particular, are critical components that must endure moderate thermal loads (200–300 °C during aggressive braking), cyclic mechanical stresses, and exposure to corrosive road environments. GL 8413 billets consolidated by FAST can be forged into caliper bodies or mounting brackets, offering excellent dimensional stability and toughness. Forging after FAST densification enhances fatigue resistance and impact tolerance, ensuring that calipers maintain structural integrity under repeated braking cycles and high clamping forces. The composite’s rare‑earth intermetallic phases resist creep and deformation under sustained mechanical stress, while ceramic dispersoids stabilize grain boundaries and provide oxidation resistance. This dual reinforcement system ensures that calipers remain reliable even after prolonged exposure to heat, brake dust, and corrosive road salts. From a performance standpoint, GL 8413 calipers deliver weight savings compared to steel or cast iron, reducing unsprung mass. Lower unsprung weight improves vehicle handling, ride quality, and responsiveness, especially in high‑performance or electric vehicles where efficiency gains are critical. The material’s machinability also allows for precision CNC finishing, enabling tight tolerances for piston bores and mounting interfaces. By adopting GL 8413 for brake caliper components, automotive manufacturers can achieve lighter, more durable braking systems that enhance both performance and efficiency, while maintaining reliability under real‑world operating conditions

Solar Receiver Housings Formed Through FAST

Concentrated solar power (CSP) receivers and other high‑temperature energy systems operate in environments characterized by intense cyclic thermal shocks, rapid heating and cooling, and sustained exposure to elevated temperatures. Components such as receiver housings, manifolds, and thermal management blocks must maintain dimensional precision and mechanical stability despite these demanding conditions. Any distortion or microstructural degradation can compromise system efficiency, reduce service life, and increase maintenance costs. GL 8413 billets consolidated by Field Assisted Sintering Technology (FAST) provide a dense, refined microstructure that is highly resistant to creep and grain coarsening. FAST enables the direct formation of complex near‑net‑shapes, minimizing material waste and reducing the need for extensive secondary processing. These near‑net‑shapes can then be CNC‑machined to final tolerances, allowing for intricate geometries such as receiver housings with integrated flow channels, manifolds with precise porting, or thermal management blocks with optimized heat transfer surfaces. This combination of FAST and CNC machining ensures both structural integrity and dimensional accuracy, critical for components that must interface seamlessly with other system elements. From a functional standpoint, GL 8413’s high thermal conductivity enables rapid heat transfer, improving the efficiency of CSP receivers and other energy systems. Its elevated specific heat capacity buffers temperature spikes, reducing thermal gradients and lowering the risk of distortion or cracking. This thermal resilience translates into longer service life, reduced downtime, and improved overall system reliability. Additionally, the composite’s oxidation resistance protects surfaces from degradation in high‑temperature, oxygen‑rich environments, further extending component durability.